For Conveyor belt

Conveyor Belt Perforating Machine

Belt ventilation hole puncher

Timing belt hole punching machine

Food-grade belt perforator

Oil drainage conveyor belt perforator

Vacuum conveyor belt hole cutter

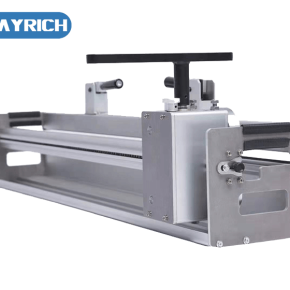

Conveyor Belt Perforating Machine

- Professional Industrial Punching Solution

Product Overview

Our high-performance conveyor belt perforating machine is designed for precision punching of various industrial conveyor belts. Utilizing advanced CNC technology, it ensures accurate, consistent, and efficient perforation for rubber, PVC, and composite conveyor belts.

Key Features

Precision Punching

CNC-controlled for ±0.1mm accuracy

Multiple hole diameter options for diverse applications

Programmable patterns for complex layouts

High-Speed Production

Fully automated operation – 30-50 holes per minute

Continuous 24/7 operation for maximum productivity

Quick-change drills minimizes downtime

Durable & Reliable

High-strength alloy steel drilling tools for long service life

Fully enclosed safety guard for operator protection

Low-maintenance design reduces operating costs

Technical Specifications

| Parameter | Specification |

|---|---|

| Belt Width Range | 1600mm or custom made |

| Hole Diameter Range | 3-20mm |

| Punching Speed | 30-50 holes/min |

| Positioning Accuracy | ±0.1mm |

| Power Supply | 380V/220V 50Hz |

| Machine Dimensions | 2600×1500×1800mm |

| Machine Weight | Approx. 1000kg |

Applications

Perforated conveyor belts are widely utilized across industries due to their breathability, drainage capabilities, and precise positioning functions. Below are the major application sectors and specific uses:

1. Food Processing Industry

Baked Goods: Used in cooling lines for cookies and bread, where perforations improve airflow and prevent product sticking

Fried Foods: Oil drainage belts (e.g., for fries, fried chicken) with holes for rapid grease removal

Fruit/Vegetable Washing: Perforated drainage belts in cleaning lines for efficient dehydration

Frozen Foods: Maintain flexibility at -40°C (often made of PU perforated belts)

2. Packaging & Logistics

Parcel Sorting Systems: Holes align with robotic suction cups (typical 3-5mm diameter)

Bottle Line Positioning: Photoelectric sensors use perforations for precision alignment (≤0.5mm tolerance)

Vacuum Conveying: Gentle transport of electronics/cardboard boxes

3. Electronics Manufacturing

PCB Production: Anti-static perforated belts for circuit board handling (surface resistance 10^6-10^9Ω)

SMT Pick-and-Place: High-precision alignment holes for component mounting (±0.1mm accuracy)

Display Glass Transport: Specially cushioned belts minimize micro-cracks

4. Automotive Industry

Welding Lines: Heat-resistant metal belts withstand 600°C welding sparks

Painting Workshops: Corrosion-resistant belts for spray booth ventilation

Parts Cleaning: Stainless steel belts in high-pressure wash systems

5. Environmental & New Energy

Solar Panel Production: Wafer dehydration belts (1-2mm micro-perforations)

Lithium Battery Electrode Drying: PTFE belts for continuous 200°C operation

Wastewater Treatment: Heavy-duty belts for sludge dewatering

6. Specialty Industrial Applications

Mining Screening: Wear-resistant rubber belts

Paper Manufacturing: Vacuum-perforated belts for smooth sheet transfer

Printing Machinery: Synchronized timing belts ensure ±0.05mm registration

Why Choose Our Punching Machine?

✅ 15+ Years of Expertise – Specialized in conveyor belt processing equipment

✅ Custom Solutions – Tailored to your specific production needs

✅ 24/7 Support – Nationwide service network & fast response

✅ Quality Assurance – Rigorous pre-delivery testing

✅ Energy-Efficient – Eco-friendly, low-power consumption

Contact Us Today!

INQUIRY

LATEST NEWS

CONTACT US

Contact:

Phone: 0086-15669710783

E-mail: echowlq@163.com

Whatsapp:0086-15669710783

Add: 9th Floor, Building 1, No.28, Henghe 3rd Road, Ouhai Economic Development Zone, Wenzhou City, Zhejiang, China.