For Conveyor belt

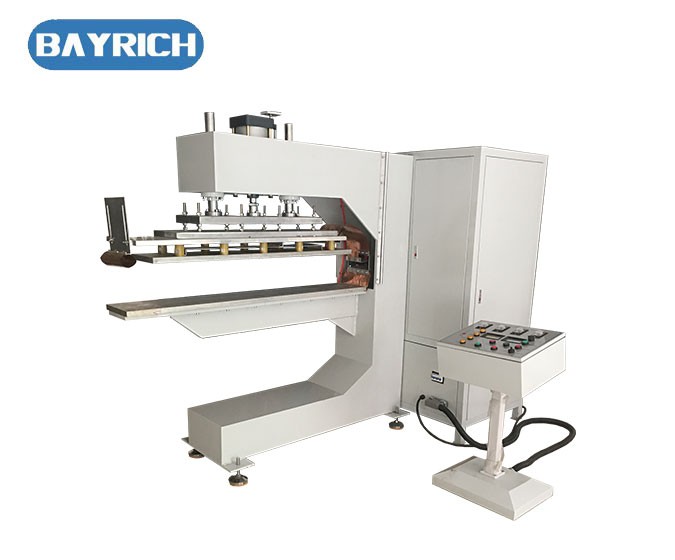

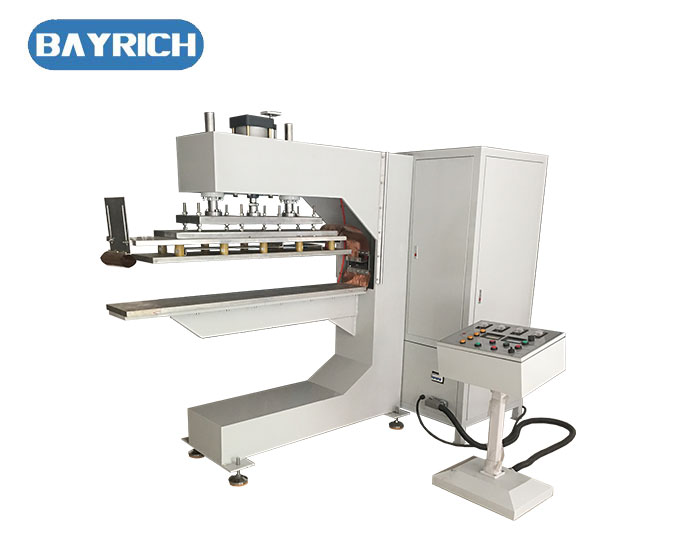

PU/PVC Conveyor Belt Sidewall and Cleat Welding Machine

Our High-Frequency (HF) Welding Machine is specially designed for welding sidewalls and cleats onto PU/PVC conveyor belts, ensuring strong, durable, and seamless bonds. Ideal for industries such as mining, food processing, logistics, and bulk material handling, this machine delivers high-speed, precision welding with superior peel strength and wear resistance.

High-Frequency (HF) Welding Machine for Conveyor Belt Sidewalls & Cleats

Introduction

Our High-Frequency (HF) Welding Machine is specially designed for welding sidewalls and cleats onto PU/PVC conveyor belts, ensuring strong, durable, and seamless bonds. Ideal for industries such as mining, food processing, logistics, and bulk material handling, this machine delivers high-speed, precision welding with superior peel strength and wear resistance.

|  |  |

| Basic type | with protect cover and mobile control | for treadmill belt |

Key Features

✔ High-Frequency (RF) Welding Technology – Ensures fast, uniform heating for consistent seam quality.

✔ Custom Welding Dies – Tailored for T-type, L-type, or wave-shaped cleats and sidewalls (10-100mm height).

✔ Adjustable Power (5-20kW) – Suitable for PVC, PU, and rubber-coated conveyor belts.

✔ PLC Control System – Precisely sets welding time , temperature, and Current.

✔ Automatic Alignment – Ensures ±1mm precision for perfect sidewall and cleat positioning.

Applications

Mining & Quarrying – Reinforced cleats and sidewalls for steep-angle conveyors.

Food & Beverage – Hygienic, seamless PU sidewall welding (no adhesive needed).

Packaging & Logistics – High-strength PVC belt cleats and sidewalls for heavy loads.

Bulk Material Handling – Durable sidewall sealing to prevent spillage.

Why Choose Our HF Welding Machine?

✅ Faster than Gluing – Welds in 10-30 seconds per cleat/sidewall (vs. hours for adhesive curing).

✅ Stronger Bond – Peel strength ≥80% of base belt, resistant to impact & abrasion.

✅ Low Maintenance – Robust construction with easy-to-clean copper electrodes.

Technical Specifications

Model: | HF-10KW |

High frequency power: | 10KW |

Power supply voltage: | 380V 50/60Hz |

Frequency: | 27.12MHz |

Input power: | 18KVA |

Rectifier: | Silicon Diode |

Oscillator: | E3069 |

Maximum pressure: | 500KGS |

Electrode spacing: | 150MM |

Upper electrode size: | 400x500mm can be customized |

Lower electrode size: | 500x800mm can be customized |

Welding time: | 0-10S adjustable |

Capacity: | 4000 times/8H |

Pressurization method: | pneumatic drive |

Custom Solutions Available

We provide tailor-made HF welding machines for:

Extra-long sidewalls and cleats (up to1500mm)

Automated conveyor belt cutting and welding lines

Contact Us Today!

Looking for a reliable conveyor belt sidewall and cleat welding machine? Get a free quote and technical consultation now!

INQUIRY

LATEST NEWS

CONTACT US

Contact:

Phone: 0086-15669710783

E-mail: echowlq@163.com

Whatsapp:0086-15669710783

Add: 9th Floor, Building 1, No.28, Henghe 3rd Road, Ouhai Economic Development Zone, Wenzhou City, Zhejiang, China.